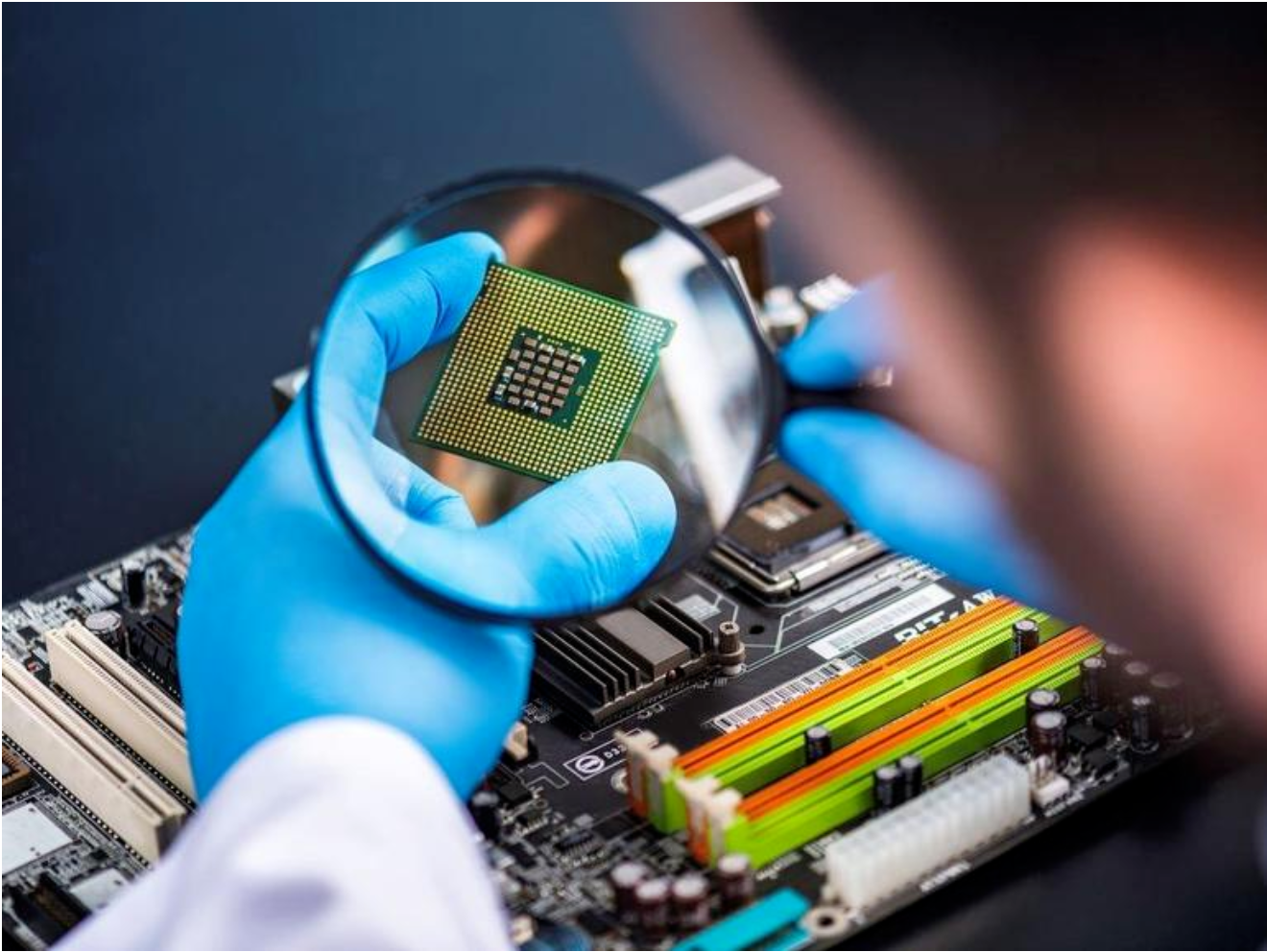

Due to the huge potential profits for counterfeiters, today's component counterfeiting methods are more sophisticated, such as using flawless component coatings/platings and seemingly perfect documentation.

Counterfeit electronic components can be disguised in many ways. A counterfeit is defined as “an imitation intended to pass off as genuine in a fraudulent or deceptive manner in order to obtain a profit.”

Metrans is verified distributor by manufacture and have more than 30000 kinds of electronic components in stock, we guarantee that we are sale only New and Original!

In the semiconductor field, counterfeit electronic components include:

- Non-functional or obsolete products are relabeled as good and resold;

- Used original parts are relabeled, repackaged, and passed off as new;

- Rebranding a product that functions well but does not meet standards and resells it as a higher specification product at an increased price;

- Unauthorized functional copies;

- Original authenticity with fake traceability documents and certificates of authenticity.

Today, we are able to pass the AS6081 standard visual test to identify fake manufacturer logos and IC packaging fakes where the internal chips do not comply. Due to the huge potential profits for counterfeiters, today's component counterfeiting methods are more sophisticated, such as using flawless component coatings/platings and seemingly perfect documentation.

Quality does not mean reliability

There are actually many risks faced by consumers, and it is common to mistakenly believe that "testing" can provide 100% quality assurance.

In fact, testing also includes many types. Many anti-counterfeiting measures only cover a certain degree of visual, re-marking and X-ray testing. These tests can identify some simple fakes, but cannot identify complex fakes.

Here are some examples of how counterfeit products can reduce long-term reliability.

- Using corrosive chemicals or mechanical grinders to remove the original external markings during remarking may result in damage to the internal bonding or substrate of the device. In addition, chemical residues during the cleaning process will gradually enter the interior and contaminate the device, eventually leading to bonding pad or bonding wire failure.

- Unauthorized handling and storage that does not comply with AS6496 standards may cause moisture and ESD (electrostatic discharge) damage to the device. This risk exists for products purchased through unauthorized channels, regardless of date code.

- The process of recycling used semiconductor devices from old PCBs can cause catastrophic heat damage and mechanical damage. Recycling ICs from PCBs is often the last step in the end-of-life process, and end-of-life products may be exposed to uncontrolled storage environments during recycling. IC is exposed to an environment with high water and salt content for a long time. The reliability of second-hand products produced through this process is questionable.

Third-party testing cannot guarantee that every fake will be identified, nor can it guarantee the reliability of the product.

At its most basic, third-party testing includes one or more of the following:

- Documentation and visual inspection: Professionally counterfeit parts may not be identified, while traceability documents and certificates of authenticity are often forged.

- X-ray inspection: May not detect devices that have been fraudulently relabeled and reused, or devices that have failed testing but have been recycled and reused.

- Basic continuity or functional testing: Unable to detect devices that have been fraudulently relabeled and reused.

- Comprehensive functional testing: The datasheet provides only a portion of the features tested by the original component manufacturer (OCM).

Has functionality been tested over the full temperature range?

When functionally testing a device, it is important to cover all possible faults. If the test coverage is less than 100%, there may be some undiscovered faults, which are called "residual faults". These "residual faults" may cause problems in actual use of the device, so ensuring test coverage is very critical.

When performing device testing, coverage of as many faults as possible, as well as accurate fault simulation, need to be considered. AS6171 is a standard that imposes requirements for more rigorous testing of devices purchased through independent distribution channels because there may be more uncertainty about the history and authenticity of these devices. However, in practice these requirements are often ignored, which can lead to undetected failures and other problems.

The only way to fully guarantee that a device will operate according to specifications is to test it using OCM's test process. However, even the most basic MCU testing requires significant development work and manual investment, which can require thousands of manual development hours. This highlights the high degree of specialization and complexity required when conducting device testing.

Third-party testing houses are unable to replicate these complex testing processes and often can only perform partial electrical or functional testing.

What exactly does "100% authorized and tested" mean?

No one wants to be deceived by counterfeit products, and purchasing shoddy products can have very serious consequences. For example, if substandard critical components are used in commercial airliners, missiles, or life-saving medical equipment, the equipment may fail during use, leading to serious consequences. Therefore, it is very important for corporate purchasers to ensure that the devices they purchase are genuine and meet specifications and quality standards.

The ultimate tool in the fight against counterfeit products

Products provided by fully authorized distributors comply with SAE Aerospace Standard AS6496. This means that the origin of its products is traceable and guaranteed, authorized by OCM. Since these products are procured from OCM, they are not subject to any quality or reliability testing, which guarantees the quality and performance of the products offered.

Suppliers who are not fully authorized may claim that their products comply with AS6171/4. However, simply by providing AS6171 test results, it is impossible to prove whether the device was purchased directly from OCM or from other channels. This may reduce the potential risk, but it cannot completely eliminate it. Therefore, companies still need to carefully consider factors such as supplier authorization and testing methods when purchasing components.